From Reactive to Proactive: Developing a Strategic Procurement Plan for Your SMB

Modern supply markets reward preparation and punish improvisation. Price spikes, logistics bottlenecks, and shifting compliance rules now arrive with little warning. Small and mid-size businesses that once relied on ad-hoc buying discover that opportunistic tactics break down when volatility strikes. A strategic procurement plan replaces guesswork with foresight, turning purchasing into a lever for resilience and profit.

Why SMB Procurement Must Evolve

Reactive procurement typically surfaces when a department realises supplies are low, phones three vendors, and chooses the first acceptable quote. That habit keeps operations moving but leaves no room for price negotiation, risk screening, or performance tracking. A proactive model, by contrast, studies spending patterns, aligns sourcing with corporate strategy, and commits to continuous improvement. Even modest businesses gain measurable advantages:

- Lower total landed costs through consolidated orders

- Reduced stock-outs and production stoppages

- Faster supplier onboarding with standardised risk checks

These outcomes arise only when purchasing is planned, measured, and refined against clear objectives. With the correct procure-to-pay software, organizations can transform their whole accounting, turning it into a proactive mechanism, able to prevent problems instead of solving them post factum.

The Business Case for a Strategic Procurement Plan

Visibility is limited by sporadic purchasing. Cash-flow projections falter and volume discounts disappear in the absence of category-level understanding. The benefits of a formal strategic procurement plan include:

- Budget discipline: Project leads stay inside budgetary bounds thanks to real-time spend analytics.

- Supplier leverage: Better terms are justified by steady order quantities.

- Risk reduction: Disruptions are lessened by a variety of sources and recorded backup plans.

- Process efficiency: Standard approval procedures reduce administrative burden and cycle times.

Step 1: Assess Current Procurement Maturity

Conduct a Spend Analysis

Compile the previous 12 months’ worth of invoices, credit card statements, and contract information. Sort by business unit, commodity, and supplier to identify maverick purchases and concentration risk.

Map the Supplier Base

Rank vendors by criticality, annual spend, on-time delivery, and quality scores. This segmentation highlights strategic partners versus transactional suppliers.

Review Policies and Workflows

Document every touchpoint—from requisition to payment—to locate manual bottlenecks, duplicate approvals, or compliance gaps. The assessment becomes the baseline against which progress will be measured.

Step 2: Set Clear Procurement Objectives

A strategic procurement plan succeeds only when targets reinforce broader business goals. Typical objectives include:

- Percentage cost reduction in top-five categories

- Dual sourcing of critical components within nine months

- 95 percent on-time, in-full delivery rate

- Expansion of certified diverse suppliers by 20 percent

Ensure each objective is SMART—specific, measurable, achievable, relevant, and time-bound—so accountability never drifts.

Step 3: Design the Strategic Procurement Framework

Spend Visibility & Data Governance

Establish a single source of truth, populated by automated purchase-order feeds and validated coding rules. Accurate data forms the bedrock of every decision.

Supplier Segmentation & Relationship Management

Apply the Kraljic matrix or a similar model to classify suppliers—strategic, leverage, bottleneck, routine—and tailor engagement levels accordingly. Strategic partners receive joint-process improvements; routine suppliers follow low-touch e-catalogue channels.

Category Management Roadmaps

For each high-impact category, outline sourcing waves, demand forecasts, and negotiation calendars. Category teams use market intelligence to time contracts and hedge against price swings.

Risk & Compliance Controls

Create a supplier-risk register covering financial health, geopolitical exposure, and ESG standing. Link thresholds to mitigation actions and escalation paths.

Technology Enablement

Automated approval workflows, e-sourcing portals, and AI-driven price benchmarks accelerate execution while preserving governance.

Step 4: Implementation & Change Management

Careful rollout determines whether brilliant design translates to daily practice.

- Pilot First– Select a business unit with receptive stakeholders to trial new processes and tools.

- Iterate– Capture metrics such as PO-cycle time and stakeholder satisfaction, then refine workflows before scaling.

- Champion Network– Identify influential staff who promote adoption, answer questions, and surface feedback.

- Training & Documentation– Provide role-based guides and micro-learning modules to reinforce correct usage.

Repeated communication keeps momentum and prevents regression to old habits.

Step 5: Measure, Review, and Optimise

Track KPIs and Benchmark Progress

Monthly dashboards should cover savings realised, percentage of automated three-way matches, supplier on-time delivery, and policy compliance rates.

Continuous Improvement Loops

Quarterly business reviews evaluate gaps, update risk registers, and schedule fresh sourcing waves. A living strategic procurement plan adapts to market shifts rather than sitting in a drawer.

Tools and Platforms That Accelerate Proactive Procurement

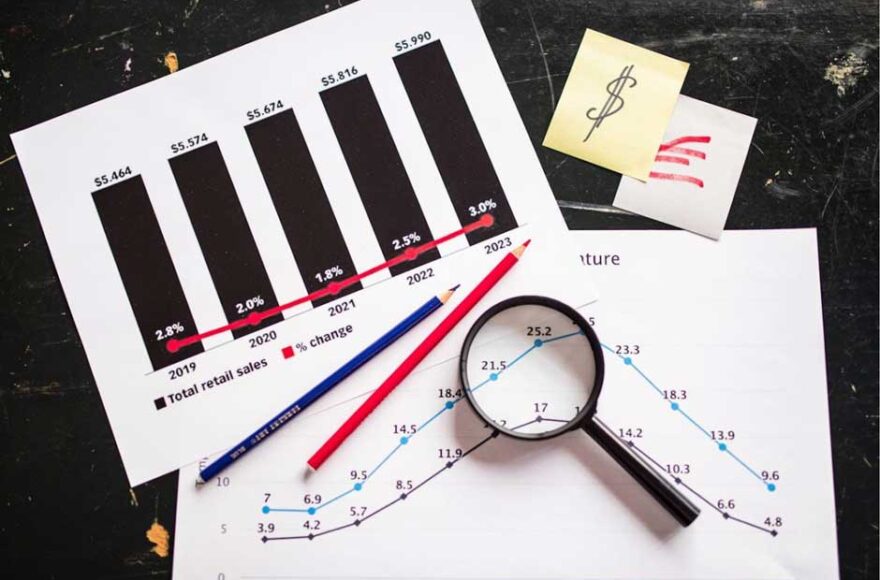

- Spend Analytics & BI– Transform raw transaction data into visual dashboards that spotlight anomalies and savings opportunities.

- E-Sourcing Suites– Standardise RFQ issuance, bid evaluation, and award decisions.

- Contract-Lifecycle Management– Track clauses, renewal dates, and performance obligations.

- Integrated Procure-to-Pay Automation– Links requisition, purchase-order, receipt, and invoice data, eliminating re-keying and late payments—essential for smaller teams with limited headcount.

Conclusion: Turning Procurement into a Growth Engine

Small and mid-size businesses rarely enjoy vast cash reserves or expansive supplier rosters. That constraint makes a strategic procurement plan even more vital. By assessing maturity, setting explicit objectives, embedding data governance, and committing to continuous improvement, organisations shield themselves from volatility and unlock margin previously hidden in fragmented processes.

When the next price shock or supply disruption emerges, firms that transitioned from reactive to proactive will respond with confidence, armed with accurate data, flexible contracts, and a culture of strategic thinking.

FAQ

What is the difference between tactical and strategic procurement?

Tactical procurement focuses on immediate needs and price, whereas a strategic procurement plan aligns sourcing with long-term objectives, risk control, and performance metrics.

How long does it take an SMB to implement such a plan?

Timelines vary, but many small firms complete assessment, design, and pilot phases within six to nine months, expanding enterprise-wide in the following year.

Which KPIs matter most for small businesses?

Cost-avoidance rate, PO-cycle time, supplier on-time delivery, and compliance with negotiated contracts provide a balanced view of savings and service.

Do SMBs need dedicated procurement technology?

Cloud solutions scale to transaction volume and often pay for themselves through faster processing, reduced errors, and actionable analytics.

How often should the plan be reviewed?

Quarterly reviews capture market changes, with a full strategic refresh every 12 months to reassess goals and the supplier landscape.